Laser date coding technology is increasingly favored by manufacturing companies due to its advantages such as efficiency, clarity, and environmental friendliness. In industrial production, the identification of dates and other key information on products is crucial for traceability, management, and supervision. With the development of manufacturing and the improvement of intelligence, laser date coding technology has gradually become one of the popular industrial applications chosen by manufacturers. This article will elaborate on the advantages of laser date coding technology and explain why more and more manufacturers are choosing laser date coding.

1、 Production efficiency

Laser date coding technology has become one of the choices for manufacturing manufacturers due to its production efficiency. Compared to traditional date coding methods such as inkjet printing or inkjet coding, laser coding technology is simple to operate, fast, and can improve production efficiency. Through laser coding equipment, the production line can achieve fast and accurate coding of dates and other information, avoiding the need for waiting for drying time or additional processing steps in traditional methods, thereby shortening the production cycle and improving production efficiency.

2、 Durability and clarity

Laser coding marks are durable, clear and readable, and are not easily erased or blurred. This feature allows the date and information on the product to remain clear for a long time, which is beneficial for the traceability and identification of the product in various stages such as transportation, storage, and sales. The persistence and clarity of product information are crucial for maintaining product quality and brand image, and are also one of the reasons why manufacturers choose laser date coding technology.

3、 Environmental protection and energy conservation

Compared to traditional coding methods, laser date coding technology does not require the use of ink or chemical solvents, reducing environmental pollution and minimizing the need for additional consumables. Laser coding equipment produces almost no noise or waste during operation, which is in line with today's green and environmentally friendly production concept. Today, with the increasing awareness of environmental protection and energy conservation, the environmental advantages of laser date coding technology have become important considerations for manufacturers when choosing.

4、 Widely applicable

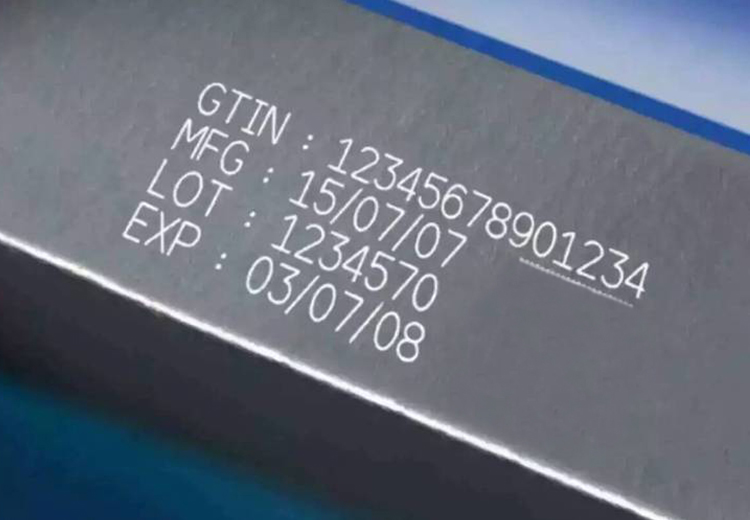

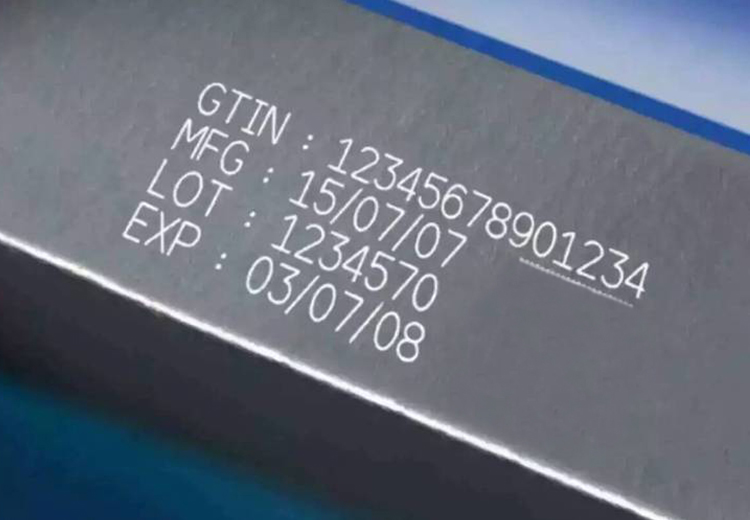

Laser date coding technology has a wide range of applicability and can be used for marking various materials, such as metal, plastic, ceramics, etc. This enables laser date coding technology to be applied to different types of products, meeting the needs of manufacturing manufacturers for diversity and universality of marking equipment. Whether in the fields of food, medicine, automotive, electronics, etc., laser date coding technology can provide high-quality marking effects to meet the needs of different industries and products.

5、 Quality Management and Traceability

Laser date coding technology can achieve highly accurate marking, which is helpful for product quality management and traceability. By laser coding, clear serial numbers, batch numbers, and other information can be marked on the product for traceability throughout the product lifecycle, improving the efficiency of quality monitoring and management. This is of great significance for ensuring product quality and enhancing product brand reputation, which is conducive to establishing a good brand image for enterprises.

Laser date coding technology has become an increasingly popular marking method for manufacturing companies due to its performance, durability, environmental characteristics, wide applicability, and support for quality management. With the continuous advancement of technology and the expansion of application scenarios, laser date coding technology will continue to play an important role in the future, actively promoting the improvement of production efficiency, quality management level, and environmental awareness in the manufacturing industry.

Some content is reposted from the internet. Copyright belongs to the original authors. If infringement occurs, please contact us for removal. Content involving franchising or investment carries risks - exercise caution when making decisions.